Our Anodizing Process

1 ·

2 ·

3 ·

❹ ·

5 ·

6 ·

7 ·

8 ·

9

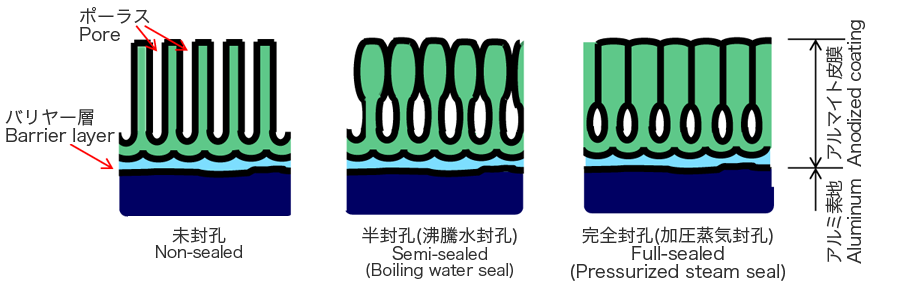

About sealing process

(Type of sealing and functions)

The coating produced after the anodizing process has numerous micropores. The process of closing the pore by hydration reaction is called sealing process. Generally, there are three types of sealing treatment methods, and among them, the most suitable for semiconductor manufacturing equipment is:1. Boiling water seal, 2. Pressurized steam seal.

- 1. Boiling water seal

- This is a treatment performed in hot water at 90-100 ° C. After the treatment, it becomes a semi-sealed pore.

- 2. Pressurized steam seal

- The process is performed under a pressure of 0.28 to 0.5MPa / cm3. After the process, pores are completely sealed.

As shown in the figure below, pressurized steam sealing (complete sealing) is more effective in preventing pores, which can improve physical and chemical properties such as anti-contamination and corrosion resistance.

The quality of the coating is influenced not only by anodizing treatment but also by post-treatment.