Our Anodizing Process

❶ ·

2 ·

3 ·

4 ·

5 ·

6 ·

7 ·

8 ·

9

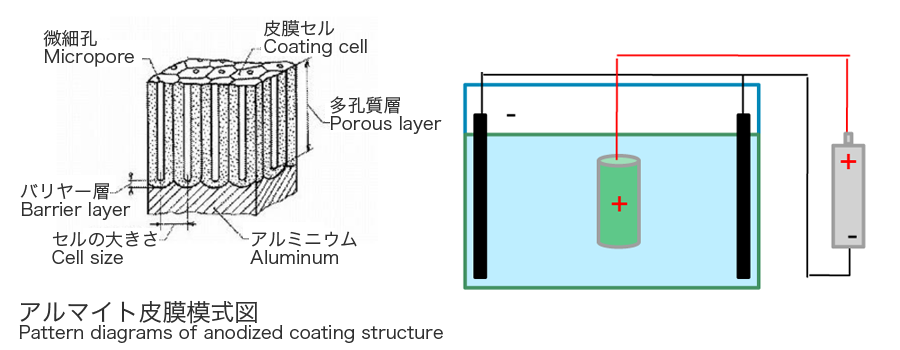

About anodizing

Unlike normal coat and paint, anodizing (anodic oxidation coating) is the coating process specifically for aluminum (alloy, mold and die-casting). Anodized coating is obtained by reforming top surface of base material.Aluminum material can be anodized by applying specific amount of current to the surface of material, being immersed in a bath of sulfuric acid, oxalic acid or organic acid as anode, while carbon etc., immersed as counter electrode at the same time.

As a result of anodizing, you will get anodized coating with growth or improvement of (1) hardness (2) corrosion resistance (3) abrasion resistance (4) insulation and so on.

Additionally, anodizing process results better crash proof in coating because of reforming surface of material, compared with normal coat and paint.