About type of anodizing

Type of anodizing, commonly used as given below;

- 1. Sulfuric acid anodizing (JIS H 8601)

- Often used for inner/outer cases of cosmetic articles and ornaments due to better staining properties, while coating thickness is thinner than expected.

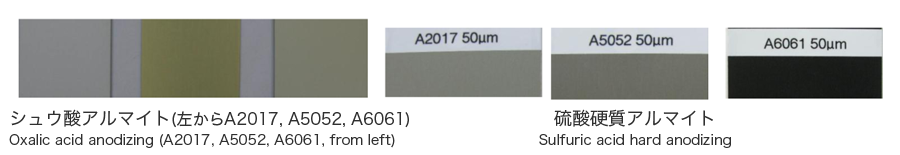

- 2. Sulfuric acid hard anodizing (JIS H 8603)

- Compared with normal anodizing, conditions of bath density, temperature and electrolysis are different. As a result, porous diameter in coating structure becomes much wide and hardness increases up to 1.5 times than normal anodizing due to growth of porous wall, while number of porous decreases.

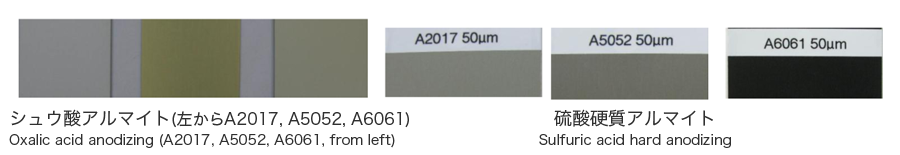

- 3. Oxalic acid anodizing (JIS H 8601)

- This method has been established in Japan. The coating has better heat resistance and often used to be applied to commodities including a kettle and a crock. Since there is no heavy atomic element inside than aluminum, both phosphorus and sulfur are not emitted.